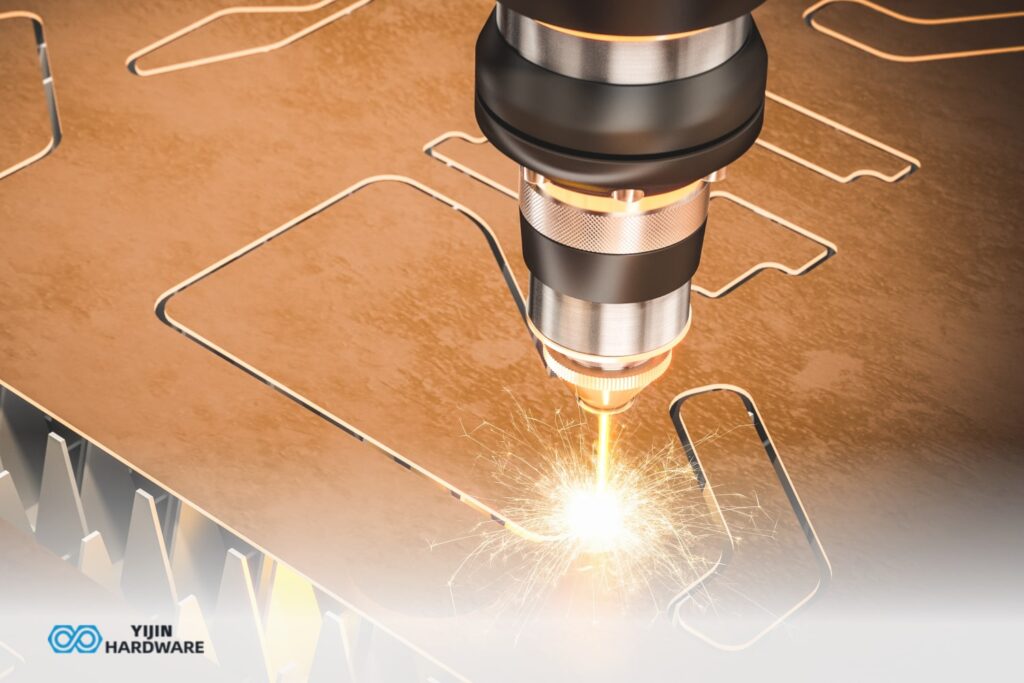

United States, 14th Nov 2024, – Yijin Hardware, a prominent CNC machined parts manufacturer, has announced the expansion of its capabilities in copper CNC machining to support industries with stringent demands for precision and quality. Known for its extensive expertise in custom-made CNC components, Yijin Hardware’s recent development aims to meet the specific needs of sectors such as aerospace, electronics, and telecommunications, where high-performance applications rely on copper’s excellent conductivity and machinability.

This strategic move by Yijin Hardware enhances its ability to deliver precise copper components for applications requiring exact specifications and reliability. With improved CNC processes and updated tooling, Yijin Hardware is set to address the unique challenges posed by copper machining, including maintaining consistent tolerances and surface quality throughout production.

“Yijin Hardware’s expansion into copper CNC machining is a commitment to meeting the exacting standards of industries where component quality is paramount,” said Gavin Yi, CEO of Yijin Hardware. “Copper’s characteristics, particularly its conductivity and durability, make it ideal for complex applications, and this development allows Yijin Hardware to deliver the precise quality and performance these sectors demand.”

Copper components are increasingly used in high-tech and environmentally sustainable applications, from telecommunications infrastructure to energy-efficient technologies. However, copper machining presents distinct challenges due to the material’s softness and thermal conductivity, which require specialized equipment and refined machining techniques. Yijin Hardware’s investment in process optimization and specialized tooling ensures that copper parts are manufactured accurately and consistently, minimizing the need for post-production modifications.

This enhancement of copper CNC machining capabilities aligns with current trends in manufacturing, where industries require parts with exact tolerances and reliable performance. Yijin Hardware’s advancements not only improve production efficiency but also contribute to sustainable practices by reducing waste and enhancing energy efficiency in manufacturing processes.

In addition to expanding copper CNC machining services, Yijin Hardware has implemented support options to assist clients in integrating copper components into their production. The company offers project consultation and design optimization, helping clients maximize copper’s material benefits in their final products. By refining designs for manufacturability, Yijin Hardware ensures a smooth transition from concept to production while maintaining project cost-efficiency and quality.

“As technology progresses, Yijin Hardware remains committed to advancing CNC capabilities that anticipate the needs of high-precision industries,” Yi added. “Ongoing investment in CNC technology will allow Yijin Hardware to remain a dependable partner to sectors requiring the highest standards in component accuracy and reliability.”

Headquartered in Shenzhen, Yijin Hardware has built a reputation for delivering custom CNC components with precision and efficiency. As a trusted supplier, the company is dedicated to supporting industries where precise engineering is critical to operational success.

For more information on Yijin Hardware’s copper CNC machining services, contact +1 626 263 5841 or email at yijing@yijinsolution.com.

Media Contact

Organization: Yijin Hardware

Contact

Person: Gavin Yi

Website:

http://yijinsolution.com/

Email:

yijing@yijinsolution.com

Contact Number: 16262635841

Country:United States

The post Yijin Hardware Expands Expertise in Copper CNC Machining for High-Precision Industries appeared first on

Brand News 24.

It is provided by a third-party content

provider. Brand News 24 makes no

warranties or representations in connection with it.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Marketwise Analytics journalist was involved in the writing and production of this article.